Refrigeration is the heart of the supermarket. We recently sponsored a webinar in collaboration with National Grocers Association for retailers who are ready to explore new tools and technologies in search of simple, cost-effective solutions for refrigeration monitoring and maintenance. This post highlights some of the conversation with OpSense CEO, Stu Gavurin moderating the discussion between Piggly Wiggly Owner, Tim Pifer and Coastal Refrigeration Technologies Owner, Dale Hall.

What are the things that keep owners up at night?

Tim: Independent grocers worry about saving money and heading off losses. There’s such an investment in inventory, across the store. Good retailers should dump everything that is in question, not just frozen products. Once you lose product, you lose sales, empty shelves, there’s the labor cost to pull product and more labor to put it back in. It can cost customers. Especially if they notice the issue first. We don’t worry about losing product any more with OpSense installed.

Dale: Tim’s success is my success. If he’s not doing well, I’ll lose a customer. It’s not just the sale today, but the sale I never get to make again. It’s the customer who goes someplace else, and gets a good cut of meat and good service. I’m worried about the customer I lose forever.

It’s terrible to add insult to injury if I have to hand Tim a bill after he’s had to toss out product.

If you have the right technology in place, you can wait until morning, if you can see the temps going back into the right range, technology can prevent a sleepless night and confirm that the change made is fixing the issue.

Technology comes with a cost, lack of technology has its own cost.

Dale: When we installed OpSense in a store, within the first month, the savings of product was greater than the cost of the installation of OpSense. If it does its job one time and saves product, you probably just paid for it, whether the tech is leak detection, temperature monitoring, that’s all tech saving you money in the long run. I’ve sat with customers and put bills together to show how they paid for technology and didn’t get the technology. Sometimes the lack of technology is in missed sales or the labor process of pulling product out of a case that’s down, and the cost of lost sales today and forever.

When is the right time to invest, repair, or augment refrigeration equipment or technology?

Tim: Every independent grocer is in a situation where they need to determine how much money to spend to correct a problem. We were operating with a system almost 40 years old. Dale and I talked about monitoring systems years ago and they were too expensive. When Dale made me aware of OpSense, it was a no-brainer. We looked at the amount of labor we were investing in washing down cases and putting products back.

What must tech provide to be of value now? What convinced you to invest?

Tim: We held off as long as we could. We knew we had a defrost cycle problem, and we knew it was going to be a sizable investment. It got to the point we were spending so much time and labor correcting problems on a daily basis. We figured if we could get our money back in a two year period, it would be worth the investment. We finally decided to stop the problems with the cases, the investment paid for itself very quickly.

Dale: There are some aspects of going to a centralized defrost system that are of value to me as a refrigeration contractor. Part is related to temperature monitoring. I can guarantee that every store manager that doesn’t have a system, thought a case was in defrost when they left at night. People are so used to a regular schedule, and come in the morning to a situation. With a monitoring system, it’s possible to look and see when it was in defrost.

There are energy savings when going to a centralized defrost system, staggering defrost cycles throughout the stores so there are not multiple high demands at one time. Energy savings is a massive thing for independent grocers. Saving money on a power bill is money in the pocket. On a rack system, it’s important to not have a lot of things in defrost at one time. It impacts refrigerant levels and suction pressures, and makes it more difficult for the system to run, and therefore more compressor failures.

How to identify key refrigeration issues?

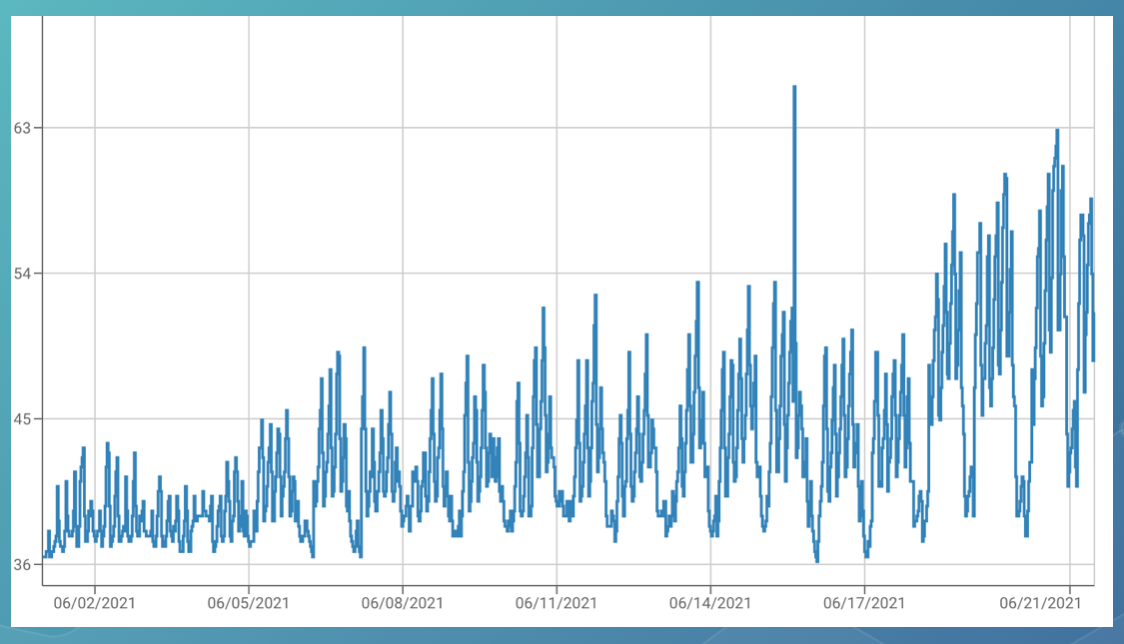

Dale: In looking at this graph and looking back at the data, we saw the baseline temperature constantly increasing. We contacted the store about the issue. They had a leak and were losing gas. We were able to find the leak and fix the leak before they lost a lot of gas and before it impacted product. Technology paid for itself here in savings on gas.

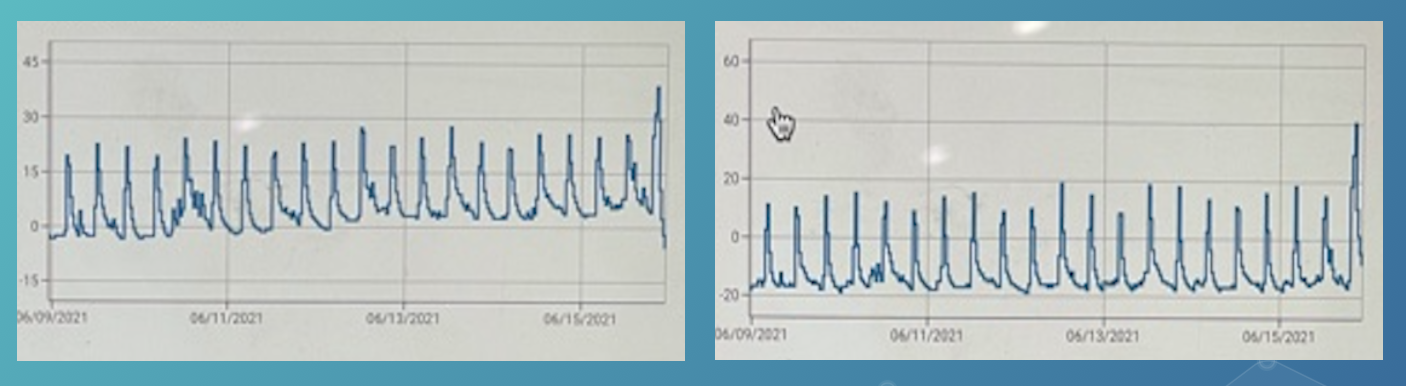

These graphs show two adjacent cases. The gradual incline of the case on the left points to airflow issues.

Dale: These two cases are adjacent to each other and on the same circuit. So it tells me the issue is with the case, not the circuit or compressor. Not a gas issue or a fan motor. Just one case started going up. So the case may be iced up. At the store level, they may decide to wash the case out and I don’t have to get involved. This saves the retailer a service call and me an unwarranted trip.

Tim: These graphs are a perfect picture of what we’re talking about, none of product in the cases was in jeopardy at that particular point. A couple more days down the road would have been different. When we can see these problems and know it’s not an immediate disaster and are able to plan correcting the fix.

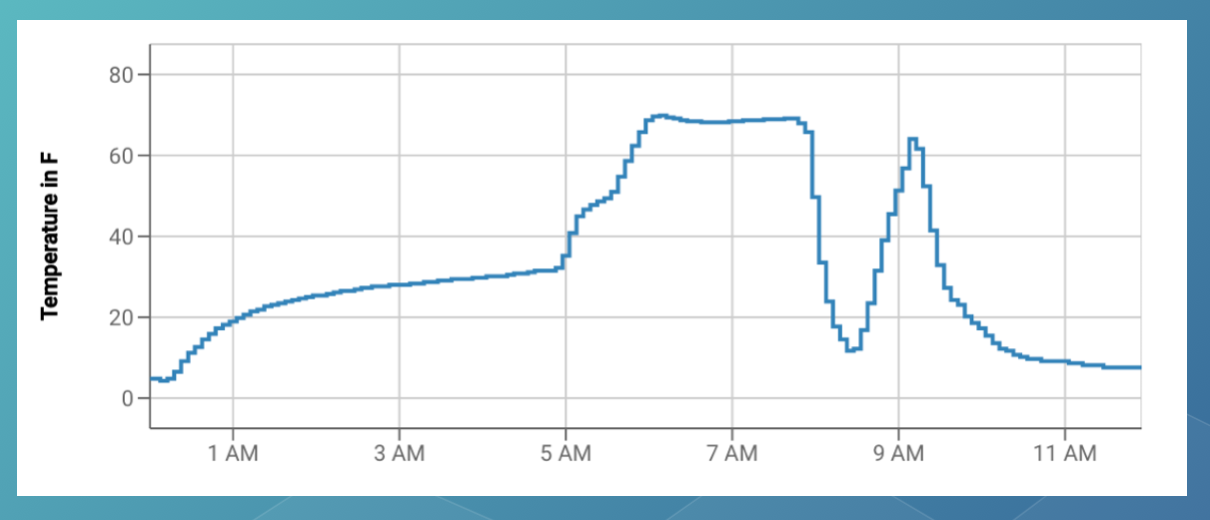

Dale: The first thing is to determine where the issue is. In this situation, a fan motor was going out on a case. It caused elevating temperatures. We determined there was an issue in the case rather than the circuit. The store just had to pull product so we could fix the fan motor without losing any product.

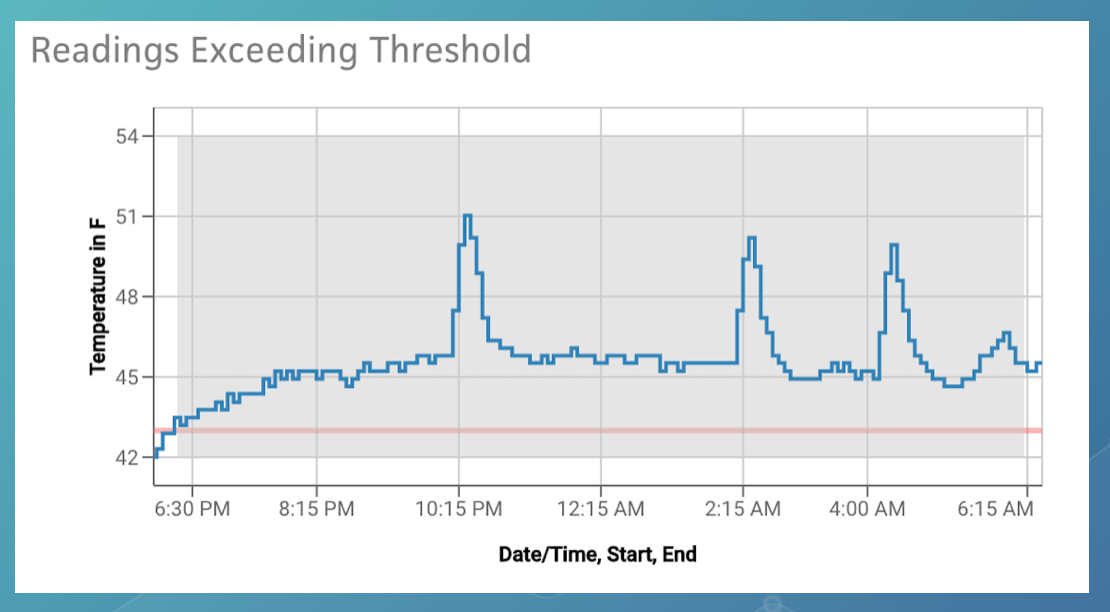

The red line is the target threshold. You can see the defrost is active and working. The staggering of the peaks indicate it’s not all defrost. The case next to it probably has a thermostat controlling it. We detected a bad fan motor within a few hours and fixed it.

Tim: Getting notified about a problem is huge and is really what gives us peace of mind. When we have a problem with a case and the case goes outside set parameters, first of all, we get a text message with this information on our phones and can look at the history. If for some reason we don’t respond, we’ll get an email and some time after that we’ll get a phone call. There’s practically no way to have a problem and not have someone be notified well in advance of it becoming a major problem. We have a total of 4 people who get notified when there’s an issue with a case. One is a junior assistant manager and it’s a great learning tool for him. I might call the manager on duty to ask about an issue and more often than not, they already have a resolution.

A month after we got the system, in the middle of the night, I got an alarm on a frozen food case, and another one, and another one. At 2:00 in the morning I dial in and see my whole frozen food case is above set-point. I went to the store and found a 200 amp breaker blew in the middle of the night. Had I not had OpSense, every bit of our frozen food would have been lost by morning. That one instance paid for the system ten times over.

How did you decide to use a combination of rack system along with temperature monitoring?

Tim: The defrost system we put in ensures that our cases go on defrost at the exact time, all the time. We don’t wonder anymore. The monitoring system gives me peace of mind. I can dial in and look at cases and know exactly what’s going on at any given time of the day no matter where I am, at the beach, at the golf course, at home with my family. I can look at the history to see when something started. I sleep better at night, knowing I won’t wake up to a store full of bad product. Even if you have a rack system, the monitoring and peace of mind, and knowing where the cases are all the time – it’s well-worth the investment.

Dale: When it comes to holidays where stores are closed or close early, and there’s not someone in the store to see the cases running warm. If you send someone in to check temps during the holiday, they want to get back to family, and might assume a warm case is in defrost. If you have a central defrost system, you can label each case and know the exact times when it’s in defrost.

Recently, I had a store with a temp monitoring system, and got an alarm for a meat cooler at 8:30 at night. Looking at the graphs, there were no peaks for defrost. So I knew this was probably iced up. Got the alarm at 8:30 at night, store closes at 9:00pm. I called the store manager and they were able to manually put the case in defrost. It melted the case down, so it can go another 8 hours. We came in the next morning, at regular time instead of overtime to replace the time clock. The store saved money by not paying an emergency service call at night, and no product was lost. I slept better that night.

If you learned something from these highlights and want to view the webinar in its entirety, the recording is now available. You’ll simply need to enter your name and email address to view it: [Watch the Recording]